Computer Numerical Control (CNC) machining is a transformative manufacturing process, allowing for the creation of highly precise parts from a wide array of materials. When leveraging an Online Cnc Service, understanding material options is crucial for project success. This guide outlines common materials available for CNC machining, helping you make informed decisions for your next project.

Metals for CNC Machining

Metals are frequently chosen for CNC machining due to their strength, durability, and thermal properties. Here’s a look at popular metal choices:

Aluminum

Aluminum stands out due to its excellent strength-to-weight ratio and natural corrosion resistance thanks to its oxidized outer layer. This makes it ideal for mechanical components requiring both strength and lightness. Different aluminum alloys offer varying properties:

- Aluminum 6061: A versatile alloy known for its weldability, strength, and corrosion resistance. Commonly used in aerospace, automotive, and consumer products.

- Aluminum 7075: One of the strongest aluminum alloys, often used in high-stress applications like aircraft parts and sporting equipment.

- Aluminum 5052: Offers higher corrosion resistance than 6061 and 7075, making it suitable for marine applications and chemical processing equipment.

- Aluminum 2A12: A high-strength aluminum alloy with good machinability, often used in aircraft structures and tooling.

CNC Aluminum Parts

CNC Aluminum Parts

Stainless Steel

Stainless steel is prized for its exceptional resistance to wear and corrosion, as well as its strength and aesthetic appeal. Various grades cater to specific needs:

- Stainless Steel 304: The most common grade, offering good corrosion resistance, weldability, and formability. Used extensively in kitchen appliances, food processing equipment, and architectural applications.

- Stainless Steel 316/316L: Enhanced corrosion resistance, especially against chlorides and acids, making it ideal for marine, chemical, and pharmaceutical applications. 316L is a low-carbon version, better for welding.

- Stainless Steel 303: Designed for improved machinability due to added sulfur, often used for screws, bolts, and shafts.

- Stainless Steel 430: A ferritic stainless steel with good corrosion resistance and formability, commonly found in appliances and decorative trim.

- Stainless Steel 201: An austenitic stainless steel with lower nickel content, offering a cost-effective alternative to 304 with comparable strength.

CNC Stainless Steel Component

CNC Stainless Steel Component

Brass

Brass, particularly Brass C360, also known as free machining brass, is favored for its excellent machinability due to its high lead content. It also offers good corrosion resistance and electrical conductivity, suitable for decorative hardware, plumbing fittings, and electrical connectors.

CNC Machined Brass Part

CNC Machined Brass Part

Copper

Copper is renowned for its exceptional electrical and thermal conductivity, alongside good strength, corrosion resistance, machinability, and ductility. This versatility makes it perfect for electrical components, heat exchangers, and plumbing systems.

Copper CNC Component

Copper CNC Component

Titanium

Titanium alloys, such as Titanium Gr5 (TC4), are characterized by their incredible strength-to-weight ratio, high toughness even at extreme temperatures, and excellent corrosion resistance. While more expensive and challenging to machine than some other metals, titanium is essential for aerospace, medical implants, and high-performance automotive parts.

Titanium CNC Machining Example

Titanium CNC Machining Example

Mild Steel

Mild steel, including grades like 1018, 1045, and A36, is a cost-effective and readily machinable option. Its lower carbon and alloying element content compared to higher carbon and alloy steels makes it suitable for general-purpose parts, structural components, and applications where extreme strength or hardness is not required.

Mild Steel CNC Parts

Mild Steel CNC Parts

Alloy Steel

Alloy steels, such as 4140, 4340, and 1215, are formulated with iron, carbon, and additional elements like vanadium, silicon, nickel, and chromium to enhance specific properties. These steels offer improved strength, hardness, toughness, and wear resistance compared to mild steel, making them suitable for gears, axles, and high-stress components.

CNC Alloy Steel Component

CNC Alloy Steel Component

Tool Steel

Tool steel is a category of carbon and alloy steels specifically designed for toolmaking. Grades like D2, A2, O1, A3, S7, and H13 offer high hardness, wear resistance, and heat resistance, essential for molds, dies, cutting tools, and forming tools.

Tool Steel CNC Machined Parts

Tool Steel CNC Machined Parts

Spring Steel

Spring steel is typically a low-alloy manganese, medium-carbon steel, or high-carbon steel characterized by a very high yield strength, allowing it to return to its original shape after significant deflection. This property is crucial for springs, clips, and flexible components.

CNC Spring Steel Part

CNC Spring Steel Part

Plastics for CNC Machining

Plastics offer a diverse range of properties, including lightweight nature, chemical resistance, and insulation, making them valuable for various CNC applications:

ABS (Acrylonitrile Butadiene Styrene)

CNC machined ABS is a cost-effective and versatile plastic ideal for production-like parts where detail and mechanical properties are important. Different types include:

- ABS: A strong, impact-resistant, and machinable plastic used in automotive parts, electronic housings, and consumer products.

- ABS Flame Retardant: Formulated to resist burning, suitable for applications requiring fire safety standards like electrical enclosures and appliance components.

- ABS Transparent: Offers clarity and impact resistance, used in protective covers, light diffusers, and display components.

CNC Machined ABS Plastic Parts

CNC Machined ABS Plastic Parts

Polycarbonate (PC)

Polycarbonate (PC) is a highly versatile and transparent thermoplastic polymer known for its exceptional impact resistance, high temperature resistance, and optical clarity. It is used in safety glasses, automotive lenses, and electronic components.

Polycarbonate CNC Component

Polycarbonate CNC Component

Nylon

Nylon, including Nylon 6 and Nylon 12, is characterized by excellent abrasion resistance, high impact strength, and good mechanical properties. It is often used for gears, bearings, bushings, and wear pads.

CNC Nylon Parts

CNC Nylon Parts

Polypropylene (PP)

Polypropylene (PP) is a lightweight, chemical-resistant, and cost-effective plastic widely used in CNC machining as sheet stock. Its applications include containers, hinges, and chemical tanks.

Polypropylene CNC Machining Example

Polypropylene CNC Machining Example

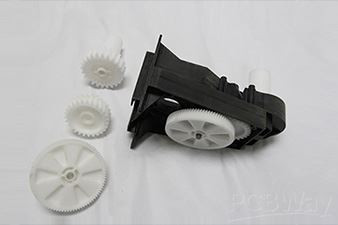

POM (Polyoxymethylene)

POM, also known as Acetal, is an engineering thermoplastic known for its high stiffness, low friction, and excellent wear resistance. Typical applications include high-performance engineering components like small gear wheels, eyeglass frames, and ball bearings.

CNC POM Component

CNC POM Component

PTFE (Polytetrafluoroethylene) – Teflon

PTFE (Teflon) is a fluorocarbon solid known for its exceptional chemical inertness, high heat resistance, and low coefficient of friction. It is used in seals, gaskets, bearings, and non-stick coatings.

PTFE Teflon CNC Part

PTFE Teflon CNC Part

PMMA (Polymethylmethacrylate) – Acrylic

PMMA (Acrylic) offers a cost-effective alternative to polycarbonate when tensile strength, flexural strength, transparency, polishability, and UV tolerance are prioritized over impact strength, chemical resistance, and heat resistance. It’s used in signage, displays, and lenses.

PMMA Acrylic CNC Machining

PMMA Acrylic CNC Machining

Polyethylene (PE)

Polyethylene (PE) is a widely used thermoplastic polymer known for its low cost, flexibility, and chemical resistance. It is used in packaging, containers, and films.

Polyethylene CNC Part

Polyethylene CNC Part

PEEK (Polyether Ether Ketone)

PEEK is a high-performance engineering thermoplastic with exceptional chemical resistance, high temperature resistance, and high strength. It is used in aerospace, medical, and automotive applications requiring demanding performance.

CNC PEEK Component

CNC PEEK Component

Bakelite

Bakelite is a thermosetting phenol formaldehyde resin, known for its electrical insulation properties, heat resistance, and rigidity. It is used in electrical insulators, handles, and knobs.

Bakelite CNC Machined Part

Bakelite CNC Machined Part

FR4

FR4 is a composite material made of epoxy resin and woven fiberglass cloth, offering good electrical insulation, strength, and flame resistance. It is primarily used as a substrate material for printed circuit boards (PCBs).

FR4 CNC Component

FR4 CNC Component

Rubber

Natural rubber offers high elasticity, abrasion resistance, and impact resistance. It’s used in seals, gaskets, tires, and vibration dampening components.

Rubber CNC Part Example

Rubber CNC Part Example

Carbon Fiber

Carbon fiber is a composite material with exceptionally high strength and stiffness, combined with lightweight properties. Carbon Fiber Plate is used in high-performance applications like aerospace, automotive, and sporting goods where weight reduction and strength are critical.

Carbon Fiber CNC Machining

Carbon Fiber CNC Machining

Custom Sourced Materials via Online CNC Service

For projects requiring materials not listed, an online CNC service like ours often provides the option to use custom sourced materials. Simply select “Custom” in the material dropdown when requesting a quote and specify your requirements. Our expert engineers will review your request to ensure compatibility and feasibility for CNC machining. This flexibility ensures that even highly specialized projects can be realized through our online CNC service.

By understanding the diverse range of materials available through an online CNC service, you can optimize your designs for performance, cost-effectiveness, and application-specific requirements. Start exploring the possibilities today and bring your ideas to life with precision CNC machining.